“What’s the Best Insulation Out There?”

We hear that question a lot, and it’s understandable. While some home services can be cut and dry -- for example, your plumber won’t have to give you a detailed explanation on PVC pipe technology -- insulation won’t be quite that direct. What is best depends on your needs.

“What’s the Best Insulation Option for Me?”

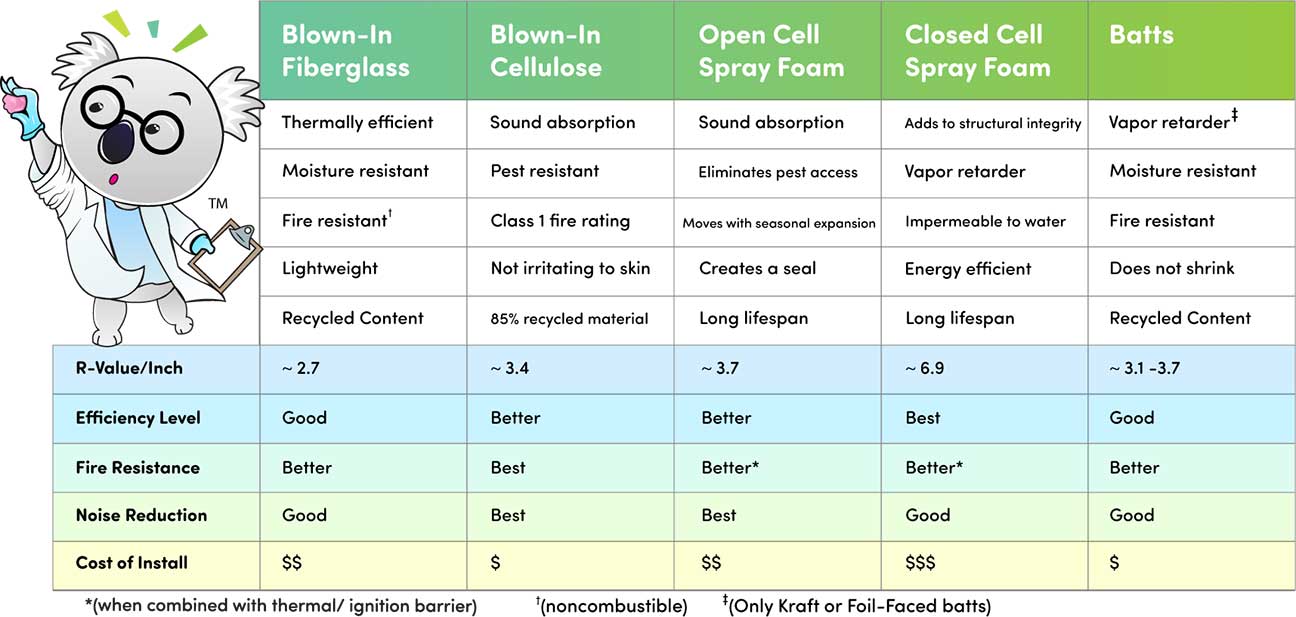

Every insulation has its pros and its cons, and depending on the type of structure that you have, one will be better than another. As you can see in the chart below, each option has its own attributes:

It is important to keep in mind that you need to balance your preferences with the structural needs of the building. For example, while you may prefer blown-in cellulose because it is pest resistant and is not made of “itchy” material, you might need to use blown-in fiberglass due to moisture issues.

Batt (Blanket) Insulation

Batt insulation is pre-cut and sized to fit most standard building sizes and are best suited for houses. This type of insulation can be used throughout the house, insulating floors, walls, and ceilings.

Batt insulation R-values, which measures the ability of the material to resist heat flow, range from 3.1 to 3.7 per inch; this means, for example, that a 3.5-inch thick batt will have an R-value of 15 and a. 8-inch thick batt will have one of 25. Depending on where you live, you will want a higher or lower R-value.

All three types of insulation offer varying degrees of sound absorption, and batts are one of the better options in general when it comes to noise reduction.

Batt insulation is the one insulation that requires additional consideration in terms of working around fixtures such as electrical boxes, writing, ductwork, and plumbing vents. Aluminum flashing, high-temperature silicone caulking, or expanding foam must be used to address these areas.

In addition, fiberglass and mineral wool are non-combustible by nature.

Spray Foam Insulation

Created on-site by combining two chemicals, isocyanate and polyol resin, spray foam insulation is an expanding foam sprayed into the areas. This type of insulation is more versatile than batts as it can be used to not only insulate walls and attics, but due to its nature, can also be used to seal air leaks such as wiring holes, plumbing vents, open soffits, and attic hatches.

The R-value per inch for spray foam varies, depending on whether or not one chooses open cell or closed cell, with closed offering the highest rating. For this type of insulation, it’s not just about the R-value, each type (open or closed) has its own properties that make it more -- or less -- effective. For example, those in a hot, dry climate are likely to use open-cell spray foam; but those who live in damper areas will want to pass since this type of insulation is more likely to trap moisture, risking mold, mildew, and structural damage. Closed-cell spray foam is more useful when it comes to vapor control.

Spray foam is not non-combustible, and will ignite at 700° F. It should always be combined with a thermal/ignition barrier.

Due to the nature of this insulation, every Koala employee is trained in line with the Spray Polyurethane Foam Association (SPFA) certification program as an assistant. They are also thoroughly trained in safety requirements to protect themselves and our customers. Over time, our technicians have the ability to become spray foam installers and Master Installers, with the ability to supervise a site and operate equipment.

Blown-In Insulation

Made up of either fiberglass, cellulose, or even mineral wool, blown-in insulation is -- literally -- blown into the space that one wishes to insulate. The small particles then join together to fill the space and create a solid barrier. Like spray foam, it can conform to the space with ease, reducing the need for additional sealing measures, such as is required when using batts.

The R-value for blown-in insulation ranges from 2.7 to 3.3 per inch, and depends on the material used as well as whether or not it is loose or dense packed. It should be noted that, while both blown-in and batts can be made with the same materials, the R-value depends on the density, meaning that blown-in fiberglass will have a lower R-value than fiberglass batts.

While fiberglass and mineral wool are non-combustible, cellulose is not. Fire retardants are added to blown-in cellulose to reduce flammability.

There is a lot to consider when it comes to choosing the right insulation for the job, and this is where Koala Insulation can help. We can guide you through the decision-making process, helping you find that balance between personal preference, structural needs, and budgetary considerations, and ensure that the insulation you choose best meets all three.

We Provide Insulation Services to the Following The Delaware Valley Areas

ARDMORE, BALA CYNWYD, BROOMALL, BRYN MAWR, GLADWYNE, HAVERFORD, MERION STATION, NARBERTH, HAVERTOWN, VILLANOVA, WYNNEWOOD, PHILADELPHIA, CONSHOHOCKEN, BRIDGEPORT, CLARKSBORO, GIBBSTOWN, GLASSBORO, HARRISONVILLE, MANTUA, MICKLETON, MOUNT ROYAL, MULLICA HILL, NATIONAL PARK, PAULSBORO, PITMAN, SEWELL, SWEDESBORO, THOROFARE, WENONAH, WESTVILLE, WOODBURY, WOODBURY HEIGHTS, CHERRY HILL, BARRINGTON, BELLMAWR, HADDONFIELD, HADDON HEIGHTS, LAWNSIDE, MAGNOLIA, MAPLE SHADE, MOUNT LAUREL, MOORESTOWN, RUNNEMEDE, AUDUBON, COLLINGSWOOD, CHESTER, ASTON, BROOKHAVEN, CRUM LYNNE, GARNET VALLEY, MARCUS HOOK, MEDIA, SWARTHMORE, WALLINGFORD, WOODLYN, CHADDS FORD, CHEYNEY, GLEN MILLS, THORNTON

Counties Served

DELAWARE, MONTGOMERY, PHILADELPHIA, GLOUCESTER, CAMDEN, BURLINGTON

Zip Code

19003, 19004, 19008, 19010, 19035, 19041, 19066, 19072, 19083, 19085, 19096, 19127, 19128, 19428, 08014, 08020, 08027, 08028, 08039, 08051, 08056, 08061, 08062, 08063, 08066, 08071, 08080, 08085, 08086, 08090, 08093, 08096, 08097, 08002, 08007, 08031, 08033, 08034, 08035, 08045, 08049, 08052, 08054, 08057, 08078, 08106, 08108, 19013, 19014, 19015, 19022, 19060, 19061, 19063, 19081, 19086, 19094, 19317, 19319, 19342, 19373